Never stop learning

This newsletter is geared toward school Facility Directors, Directors of Operations and Chief Operating Officers, but also applies to anyone else making decisions on the IAQ of their building.

Direct from EPA.gov 9/14/22:

Bipolar ionization has the potential to generate ozone and other potentially harmful by-products indoors, unless specific precautions are taken in the product design and maintenance. If you decide to use a device that incorporates bipolar ionization technology, EPA recommends using a device that meets UL 2998 standard certification (Environmental Claim Validation Procedure (ECVP) for Zero Ozone Emissions from Air Cleaners).

Question:

Why would anyone even think of installing this technology in a school?

Here’s the short answer:

The right ionization technology will LOWER negative byproducts and be considered ozone free, but that’s just the beginning. Ionization technology can do what no other technology can do. It can proactively reduce airborne pathogens, harmful particles, and VOCs right in the center of a classroom where students are breathing.

Yes. I’m sure you’ve read articles that re-stated what the EPA stated – ionizers may produce negative byproducts and ozone, but we need to understand that there are a wide variety of ionization technologies available, and some may make a bigger difference than anything you’ve done so far.

The clearer we are, the better we understand, the better decisions we make.

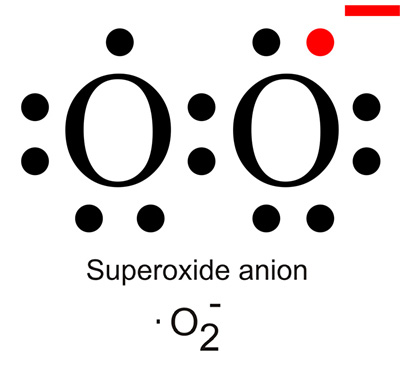

Not all ionization technologies are producing ions the same way, and some produce more effective ions than others. To be clear, the process of ionization includes an electrical charge that charges the air around it. Air is generally made up of 21% oxygen and 78% nitrogen and other gasses. To produce the most effective ions, the charge needs to be strong enough to charge an oxygen molecule (O2). The beautiful thing about physics and chemistry is that everything is defined, and for an oxygen molecule to be ionized, it needs to be charged above 12.07 electron volts (eV) (a measurement of ionization energy). Unfortunately, very few ionizers meet this criterion.

I’m going to take a wild guess and say that 99% of the people reading this did not know this critically important fact regarding ionization.

Why is it so important and what makes it more effective?

When we ionize an oxygen molecule, we are creating the strongest, most stable ion (-O2) called Superoxide Anions (An-Ions). These are negative ion clusters that act as magnets to particles, viruses, bacteria, mold, and VOCs. With particles the ions agglomerate and either make the particle big enough to increase the chances of it getting caught in a filter or weigh it down taking the particle out of the air. With viruses, bacteria and mold, the magnetic effect clings the ion to the airborne pathogen either inactivating it if it’s a virus or killing it if it’s bacteria or mold spore. With VOCs, the ions oxidize the VOCs effectively breaking them down to harmless byproducts.

When we ionize an oxygen molecule, we are creating the strongest, most stable ion (-O2) called Superoxide Anions (An-Ions). These are negative ion clusters that act as magnets to particles, viruses, bacteria, mold, and VOCs. With particles the ions agglomerate and either make the particle big enough to increase the chances of it getting caught in a filter or weigh it down taking the particle out of the air. With viruses, bacteria and mold, the magnetic effect clings the ion to the airborne pathogen either inactivating it if it’s a virus or killing it if it’s bacteria or mold spore. With VOCs, the ions oxidize the VOCs effectively breaking them down to harmless byproducts.

Where does this all occur? GREAT QUESTION. IF an ionization technology is producing Superoxide Anions, these stable ions will last up to 300 seconds – enough time for millions of these ions to be produced in the supply side of an air handling unit, travel through a long ductwork run and reach the center of a classroom, a cafeteria or gym- at a child’s height… as they or anyone else is breathing out any germs. THIS is what is called proactive IAQ technology, and it’s the very reason it is part of the future of making our IAQ better and safer.

How do we measure its effectiveness? How can we be sure it is not producing any negative byproducts and/or ozone?

Before I answer that question, it needs to be understood that for any kind of technology to be considered in use while people are occupying the same space the technology is working in, lab tests need to be passed and UL ratings need to be met. The ionization technology, or any other electronic air cleaner being proposed, should meet the EPA recommended UL2998 (Ozone Free) Rating.

That said, lab tests that are focused on proving efficacy sometimes don’t translate well in a real-world building environment where either air is not flowing much or flowing much stronger than in a lab. Real-world air also tends to carry a much wider variety of air variables than a controlled lab environment.

The key to measuring any indoor air quality technologies’ true performance in a real-world environment and making sure it is not producing any negative byproducts, is by using a 3rd party engineer to test the air before and after the technology is operating in the space where you are trying to create the best IAQ, like the center of a classroom. This is very different from commissioning the equipment (making sure the equipment installed is working) which is also important and also something we have done.

At this point, we need to use air data and metrics we know we can obtain to get a much clearer understanding of the performance and safety of IAQ technology.

What data?

The data engineers can capture include ion levels per cubic centimeter (cm3), VOC levels measured in parts per billion (ppb), Formaldehyde levels measured in ppb, particle counts from .3-micron size particles, to .5, 1.0, 2.0 up to 10 microns, and ozone levels measured in ppb.

What does the data tell us?

Ion levels are measured per (cm3). In pristine environments like mountain tops and waterfalls, ion levels could be as high as 5,000 ions cm3. When we take samples in cities especially inside buildings, these levels can drop to 300 ions cm3 or lower. It is possible to get ion levels up to 5,000 ions cm3, but realistically speaking the target should be to maintain between 1,000 cm3 to 1,500 ions cm3. In short, the denser the ion levels the safer and cleaner the air. Airborne pathogens, for example, have a much more difficult time floating through air that is densely populated with ions that are constantly clinging on and inactivating viruses, while killing bacteria and mold. When we are looking at the 3rd party ion test data, we look for a minimum increase of 500 ions cm3.

Ion levels are measured per (cm3). In pristine environments like mountain tops and waterfalls, ion levels could be as high as 5,000 ions cm3. When we take samples in cities especially inside buildings, these levels can drop to 300 ions cm3 or lower. It is possible to get ion levels up to 5,000 ions cm3, but realistically speaking the target should be to maintain between 1,000 cm3 to 1,500 ions cm3. In short, the denser the ion levels the safer and cleaner the air. Airborne pathogens, for example, have a much more difficult time floating through air that is densely populated with ions that are constantly clinging on and inactivating viruses, while killing bacteria and mold. When we are looking at the 3rd party ion test data, we look for a minimum increase of 500 ions cm3.

VOC and Formaldehyde levels are produced by a wide variety of products from paint to cleaning products, and – in many articles – electronic air cleaners. If you have the right ionization technology that is producing the most stable ions, both VOC and Formaldehyde levels should drop. There is no standard % drop we look for because every building is different. We just look for a drop. The higher the VOC and Formaldehyde levels are initially tested, the larger the percentage drop you should see once the equipment is operating.

Particle counts decreasing is another direct result of ion levels increasing. The data collected should be broken down by particle size: .3, .5, 1.0-, 2.0-, 5.0- and 10-micron size categories. The smallest from. 3 to 2.0 are the most important because these are particles that can go into your blood stream. We look for a percentage reduction. Every space is different, but we should see a decrease especially with the smallest particles.

Lastly, testing for Ozone levels is important. This is not to make sure a technology is not creating ozone. The ionization technology should be UL2998 compliant, so you know it is considered ozone free, but this test is for parents and teachers and anyone else who wants that additional security blanket that you went above and beyond. Indoors, OSHA requires less than 100 parts per billion (ppb). EPA recommend less than 75ppb and ASHRAE guidelines recommend less than 50ppb. Being that UL2998 allows for up to 5ppb of ozone, a fraction of any of the recommended thresholds, we use the 3rd party testing to confirm that no more than 5ppb of ozone is being added.

AtmosAir Solutions’ dielectric barrier discharge bipolar ionization technology (DBD BPI) checks all the boxes, and working through their national dealer, Pandemic Solutions LLC, all projects are 3rd party validated by an independent engineer firm.

The following air testing data was collected by Guth DeConzo Engineering, an engineer firm based in Troy NY. Guth DeConzo was recently asked to write the IAQ guidelines for NYSERDA that were to be used for all the NY State Public Universities. According to our records, the testing Guth DeConzo conducted represents the widest and deepest body of data to ever be collected for an ionization technology for a K-12 public school. The data is comprised of 97 spaces taken throughout the (10) school buildings for the City School District of New Rochelle (CSDNR). The spaces included classrooms, cafeterias, gyms, and offices with the air being tested in the center of the room at desk height.

B = Baseline, O = Operating

| COMPILED DATA / AVERAGE ACROSS 97 SPACES | ||||||||||

| B/O | Average Negative Ion Concentration (per cm³) | VOC (ppm) | Formaldehyde (ppm) | Particle Count (per 1 ft³) | Ozone (ppb) | |||||

| 0.3μm | 0.5μm | 1.0μm | 2.0μm | 5.0μm | 10.0μm | |||||

| B | 1,390 | 1.94 | 0.27 | 1,575,058 | 181,253 | 35,164 | 11,975 | 1,281 | 160 | 2.04 |

| O | 2,678 | 1.82 | 0.25 | 920,375 | 100,207 | 20,418 | 8,498 | 1,252 | 176 | 2.01 |

| 93% | -6% | -9% | -42% | -45% | -42% | -29% | -2% | 9% | -1% | |

Important note: The air handling systems throughout CSDNR had their filters upgraded to Merv15 before any of the AtmosAir equipment was installed. To be clear, the positive impact you see above on IAQ is after PM was done to air handlers and filters were upgraded.

There is nothing more validating than to see a large body of data collected by a 3rd party engineer showing the difference a technology is making with your IAQ.

AtmosAir’s DBD BPI was first patented in 2007 and is now in hundreds of schools, universities, NFL/NBA venues, hospitals, etc. being used in over 125 million square feet worldwide with 8,000+ systems and growing.

For a free consultation, please email Peter Cantone: peter@pandemicsolutions.net .